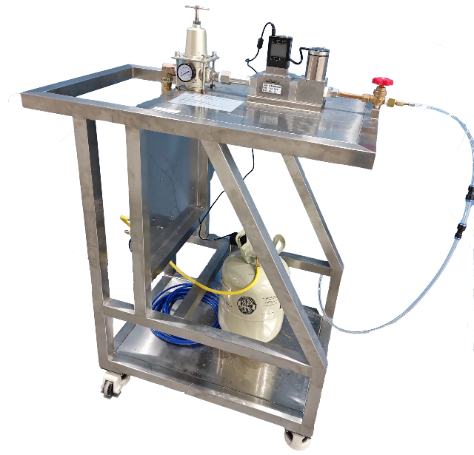

simulate refrigerant leak test device

Hand-push combustible refrigeration release mass flow control device, which can control more than 130 kinds of gases including R32, R454B, R290, R600a, etc., with high control accuracy and fast response time.

Description

This device is designed based on the requirements of household air conditioner safety standards IEC 60335-2-40, GB 4706.32, UL 60335-2-40 and household refrigerator product safety standards IEC 60335-2-24, GB 4706.13, UL 60335-2-24. Its purpose is to control the refrigerant leakage rate when simulating refrigerant leakage tests in the Appendix FF&MM of the air conditioner safety standards and the clause 22.108&22.109 of the refrigerator product safety standards.

The controllable refrigerant types include R32, R290, R600a, R454B, R454C, R454A, R702, R717, R1234yf, R143a and most non-flammable refrigerants including R404A, R407C, R410A, R507A, R23, R22 R134a. In order to meet the requirements of some special mixed refrigerants, this device can edit the mixed gas by itself. It can edit 20 kinds of mixed gases. The percentage of various gas substances in each edited gas can be freely set. Five gases can be mixed at a time. In addition to conventional refrigerants, other refrigerants that can be controlled include acetylene, air, argon, isobutane, n-butane, carbon dioxide, carbon monoxide, deuterium, ethane, ethylene, helium, hydrogen, krypton, methane, neon, nitrogen, nitrous oxide, oxygen, propane, sulfur hexafluoride, xenon, ammonia, butene, cis-butene, isobutylene, trans-butene, carbonyl sulfide, chlorine, dimethyl ether, hydrogen sulfide, nitrogen trifluoride, nitric oxide, propylene, silane, sulfur dioxide, trichlorofluoromethane, chloropentafluoroethane, hexafluoroethane, chlorotetrafluoroethane, pentafluoroethane, tetrafluoroethane, tetrafluoromethane, chlorodifluoroethane, trifluoroethane, difluorochloromethane, trifluoromethane, difluoromethane, Octafluorocyclobutane; also includes some breathing gases, barotracheal gases, fuel gas, chromatographic gases, laser gases, chimney gases, welding gases, oxygen concentrator gases, etc.

Since the device is mainly used for refrigerators and air conditioners, those products are large in size, heavy in weight, and not easy to move. Therefore, we integrated the device on a trolley, which greatly improved the operability of the device.

The device also comes with a set of customized software, which needs to be installed on a personal computer. The tester can control the test device through a personal computer; at the same time, the flow data recorded during the operation of the device can be exported using the personal computer software. The exported data format is .csv or .xls format.

This device has a simple structure and high reliability. Since the device uses almost no electrical components, it can well avoid the risk of combustible refrigerant explosion.

The control gas mass flow unit display can be selected in g/s or L/min, mL/s, the control accuracy is ±0.8% of the reading and ±0.2% of the full scale, and the control response time is 30-150ms.

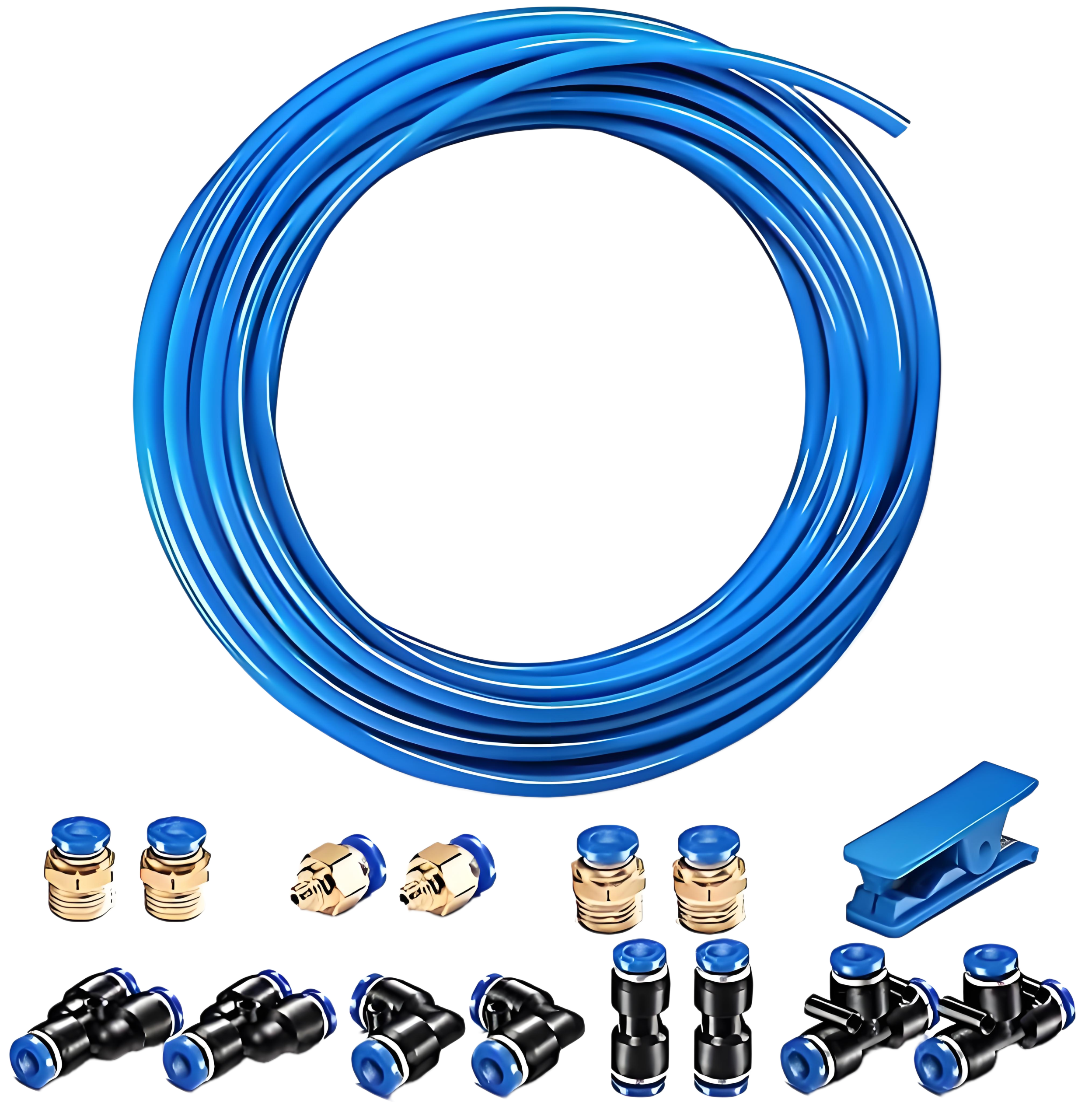

The device can be directly connected to the refrigerant tank, and the SAE 1/4 connector commonly used in the refrigeration industry is used by default. The outlet uses a PU pipe, and the PU pipe diameter can be selected from 0.7mm to 16mm.

Reviews

There are no reviews yet.