Flammable refrigerant micro-flow control device

Portable hand-held box structure, flammable refrigerant simulated refrigerant leakage refrigerant flow control device. High control, fast response time. No need to use electronic scale to control refrigerant leakage rate.

Description

Flammable refrigerant micro-flow control device

This device is designed based on the requirements of the household refrigerator product safety standards IEC 60335-2-24, GB 4706.13, UL 60335-2-24. Its purpose is to control the refrigerant leakage rate when simulating the refrigerant leakage test in chapters 22.108 & 22.109 of the refrigerator product safety standards.

According to the requirements of the standard, the leakage rate is very small. The specific calculation table is as follows:

| 22.108 | |||

| Refrigerant charge (g) | 80% of the refrigerant charge (g) | Release time (s) | Release rate (g/s) |

|---|---|---|---|

| 150 | 120 | 600 | 0.2 |

| 30 | 24 | 600 | 0.04 |

| 20 | 16 | 600 | 0.027 |

| 10 | 8 | 600 | 0.013 |

| 5 | 4 | 600 | 0.0067 |

| Through an appropriate orifice, 80 % of the nominal refrigerant charge ±1,5 g, in the vapour state is injected into a food storage compartment in a time not exceeding 10 min. | |||

22.109

| 22.109 | |||

| Refrigerant charge (g) | 50% of the refrigerant charge (g) | Release time (s) | Release rate (g/s) |

|---|---|---|---|

| 150 | 75 | 3600 | 0.02083 |

| 30 | 15 | 3600 | 0.004167 |

| 20 | 10 | 3600 | 0.00278 |

| 10 | 5 | 3600 | 0.001389 |

| 5 | 2.5 | 3600 | 0.000644 |

| A quantity equal to 50 % of the refrigerant charge ±1,5 g is injected into the considered area using a capillary tube having a diameter of 0,7 mm ± 0,05 mm. Injection is to be at constant rate over a period of 1 h and is to be at the point of closest approach of |

|||

The refrigerant used in refrigerators is basically R600a, and some are R290. The traditional method is to use an electronic scale, through a needle valve or a series connection of multiple needle valves, to control the decrease of the weight reading of the electronic scale per unit time. In order to prevent the temperature of the refrigerant tank from decreasing when the refrigerant is released from the refrigerant tank, the standard also requires that the refrigerant tank be placed in a temperature-controlled oven. This method is inconvenient to operate and has a large error.

Using a high-precision gas mass flow meter can solve this problem well.

The types of refrigerants that can be controlled by this device include R32, R290, R600a, R454B, R454C, R454A, R702, R717, R1234yf, R143a and most non-flammable refrigerants including R404A, R407C, R410A, R507A, R23, R22 R134a. In order to meet the requirements of some special mixed refrigerants, this device can edit the mixed gas by itself. It can edit 20 kinds of mixed gases. The percentage of various gas substances in each edited gas can be freely set. Five gases can be mixed at a time. In addition to conventional refrigerants, other refrigerants that can be controlled include acetylene, air, argon, isobutane, n-butane, carbon dioxide, carbon monoxide, deuterium, ethane, ethylene, helium, hydrogen, krypton, methane, neon, nitrogen, nitrous oxide, oxygen, propane, sulfur hexafluoride, xenon, ammonia, butene, cis-butene, isobutylene, trans-butene, carbonyl sulfide, chlorine, dimethyl ether, hydrogen sulfide, nitrogen trifluoride, nitric oxide, propylene, silane, sulfur dioxide, trichlorofluoromethane, chloropentafluoroethane, hexafluoroethane, chlorotetrafluoroethane, pentafluoroethane, tetrafluoroethane, tetrafluoromethane, chlorodifluoroethane, trifluoroethane, difluorochloromethane, trifluoromethane, difluoromethane, Octafluorocyclobutane; also includes some breathing gases, barometric tube gases, fuel gas, chromatographic gases, laser gases, chimney gases, welding gases, oxygen concentrator gases, etc.

The control accuracy is ±0.4% of the reading and ±0.2% of the full scale.

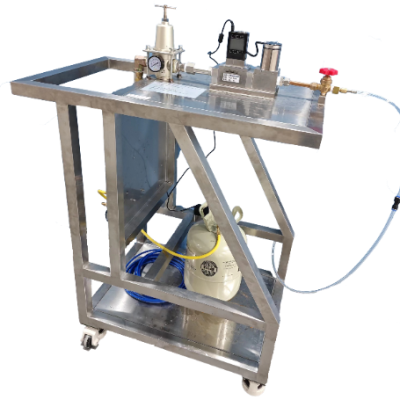

For easy operation, the device is integrated in a sturdy hand-towed box. The design of the hand-towed box can not only well protect the internal components, but also facilitate transportation and even on-site witness testing.

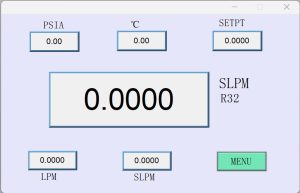

The instrument is equipped with a touch operation panel, and the interface diagram is as follows:

The internal electrical components of the instrument meet the explosion-proof requirements. The refrigerant supply connector (SAE 1/4”) equipped with the instrument are all conventional connectors for the air conditioning industry. It can be directly connected to the refrigerant tank for release operation.

The flow rate can be displayed in g/s, L/min or mL/s.

Reviews

There are no reviews yet.